Major Hardwood Provider from Allegany, NY

This lumber company specializes in the production of green and kiln dried hardwood lumber. They employ a team of professional foresters and certified timber harvesters that can help harvest both private and public timber lots. Their proven sawmill practices and drying techniques produce some of the finest high quality grade hardwood lumber in the industry.

In an on going effort to maintain their position as an industry leader, they are always making improvements with an eye toward quality, productivity and the environment! They recently installed new kilns and a new 300Hp boiler.

The Problem

Boilers generate blowdown water in order to keep the boiler clean. This water has boiler chemicals, minerals and small amounts of rust. The EPA is regulating this water – it can not go on the ground or in the sewer without treatment.

The Solution

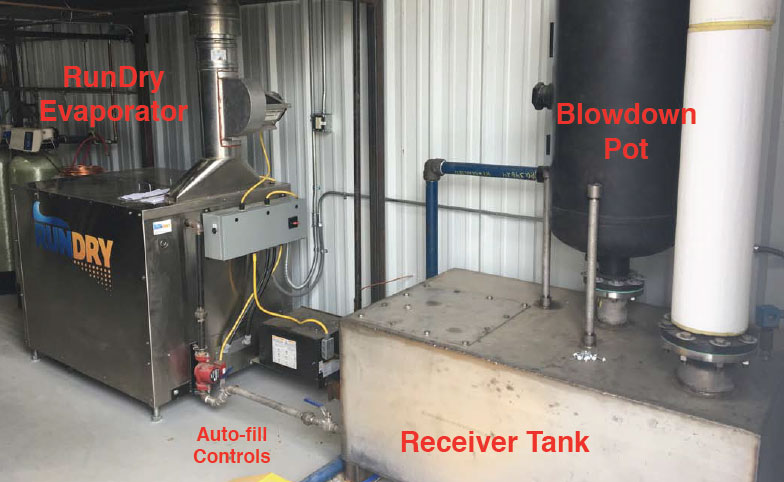

The solution was to install a RunDry Evaporator that will reduce a gallon of this water into a teaspoon of nonhazardous sludge!