Introduction

When selecting a wastewater evaporator, most buyers naturally focus on evaporation rates or operating costs. But there is another factor that quietly determines how long your investment will last: the material of construction. The alloys used in the tank and wetted parts can mean the difference between reliable service for decades, or expensive corrosion failures after only a few years.

When selecting a wastewater evaporator, most buyers naturally focus on evaporation rates or operating costs. But there is another factor that quietly determines how long your investment will last: the material of construction. The alloys used in the tank and wetted parts can mean the difference between reliable service for decades, or expensive corrosion failures after only a few years.

The Foundation: 316L Stainless Steel

For most evaporator tanks, 316L stainless steel is the baseline choice. Its low carbon content improves weldability and reduces the risk of sensitization corrosion. 316L provides good resistance to many aggressive wastewater chemicals, but it is wise to send your SDS’s to a metallurgist to get his input on material of construction for the water tank.

When to Choose Duplex 2205 Steel

2205 duplex stainless offers a major leap in durability. With a dual-phase structure, it combines high strength with excellent resistance to chloride stress corrosion cracking. Duplex materials are especially valuable for wastewater containing plating solutions, oils, and high salt concentrations.

Premium Materials: AL-6XN and C-276 for Extreme Applications

For facilities handling particularly harsh or exotic chemistries, higher alloys are worth considering:

- AL-6XN is a superaustenitic stainless steel with excellent resistance to chlorides, acids, and crevice corrosion.

- C-276 (Hastelloy) is a nickel-molybdenum-chromium alloy designed for extreme environments, offering resistance to almost every form of chemical attack.

While these alloys come at a premium cost, they can be the right choice for specialized industries where downtime is not an option.

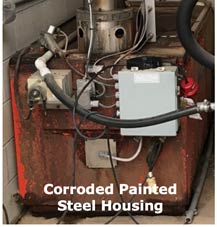

Don’t Overlook the Outer Housing

While the tank material is critical, the outer housing also matters. Some manufacturers use painted carbon steel for housings. Over time, constant exposure to water vapor and humid environments causes the paint to fail, leaving rust and corrosion behind. A better solution is 304 stainless steel for the outer housing. While not suited for aggressive wastewater contact, it resists rusting far better than painted carbon steel, and keeps the evaporator looking professional for years.

While the tank material is critical, the outer housing also matters. Some manufacturers use painted carbon steel for housings. Over time, constant exposure to water vapor and humid environments causes the paint to fail, leaving rust and corrosion behind. A better solution is 304 stainless steel for the outer housing. While not suited for aggressive wastewater contact, it resists rusting far better than painted carbon steel, and keeps the evaporator looking professional for years.

Conclusion

The right material of construction ensures your evaporator remains reliable, even under harsh conditions. Whether it is 316L for standard duty, duplex 2205 for tough wastewater, or AL-6XN and C-276 for extreme chemistries, choosing wisely protects your investment. And don’t overlook the outer housing, because nothing undermines confidence like a rusty, corroded shell on what should be a long-lasting machine.

David N Lyman, a mechanical engineer with 40 years of industrial experience. Currently the president of RunDry Evaporators™