Aerospace and defense manufacturers work under some of the strictest environmental and safety regulations in industry. Processes such as plating, anodizing, and chemical cleaning create wastewater that must be managed carefully. Hauling remains common, but it’s costly, space-intensive, and leaves facilities dependent on outside vendors. RunDry Evaporators provide a proven alternative by removing 100 percent of the water, leaving only concentrated residues to handle.

Aerospace and defense manufacturers work under some of the strictest environmental and safety regulations in industry. Processes such as plating, anodizing, and chemical cleaning create wastewater that must be managed carefully. Hauling remains common, but it’s costly, space-intensive, and leaves facilities dependent on outside vendors. RunDry Evaporators provide a proven alternative by removing 100 percent of the water, leaving only concentrated residues to handle.

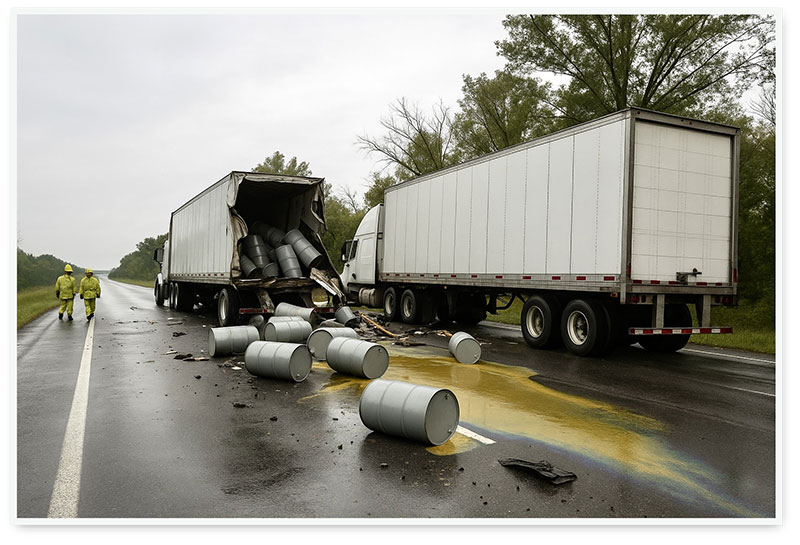

Rinse waters and process streams in this sector often contain metals, salts, and aggressive chemicals. They’re difficult to treat by conventional means, and hauling is expensive. A single facility can easily spend $200,000 or more per year on wastewater disposal. Storage of drums on site introduces additional risks, while spills in transit or improper disposal can lead to severe regulatory consequences. For companies working on government contracts or producing mission-critical components, these risks carry added weight.

RunDry Evaporators address these challenges head-on. The systems remove 100 percent of the water, reducing waste to its smallest possible form. What once filled dozens of drums becomes a manageable amount of concentrated residue. This dramatic volume reduction cuts disposal costs and frees up valuable floor space that can be used for production instead of waste storage.

The technology is built specifically for harsh industrial environments. Wetted parts use chloride-resistant alloys that can handle aggressive plating and surface treatment chemistries without corroding. This durability matters in aerospace and defense applications where downtime isn’t an option and equipment must perform reliably year after year.

The technology is built specifically for harsh industrial environments. Wetted parts use chloride-resistant alloys that can handle aggressive plating and surface treatment chemistries without corroding. This durability matters in aerospace and defense applications where downtime isn’t an option and equipment must perform reliably year after year.

Operating costs become predictable because they’re tied to energy use rather than fluctuating hauling fees. You know what it costs to evaporate a gallon of water, and that number doesn’t change when fuel prices spike or when your hauler raises rates. For facilities managing budgets and forecasting expenses, this predictability is valuable.

Beyond the financial benefits, RunDry technology strengthens compliance positions. By eliminating wastewater at the source, facilities minimize opportunities for spills or errors during transport and disposal. There are fewer manifests to track, fewer vendors to audit, and fewer points where something can go wrong. In an industry where documentation and traceability matter, this simplification reduces administrative burden and lowers risk.

The liability advantages are significant. Once waste leaves your facility, you remain responsible for how it’s handled, where it goes, and whether it’s disposed of properly. Evaporation keeps that process on site and under your control. You’re not trusting an outside company to follow regulations or hoping your waste doesn’t end up somewhere it shouldn’t. You manage the entire process from start to finish.

The liability advantages are significant. Once waste leaves your facility, you remain responsible for how it’s handled, where it goes, and whether it’s disposed of properly. Evaporation keeps that process on site and under your control. You’re not trusting an outside company to follow regulations or hoping your waste doesn’t end up somewhere it shouldn’t. You manage the entire process from start to finish.

For aerospace and defense facilities, payback on a RunDry Evaporator typically occurs within one to two years. After that, the savings continue throughout the life of the unit, which can span decades with proper maintenance. The long-term economics are compelling, but the immediate benefits of reduced waste volume, eliminated drum storage, and simplified compliance often justify the investment on their own.

In aerospace and defense, precision is everything. RunDry Evaporators offer an added layer of protection by keeping wastewater management on site and under control. By removing all of the water, they lower the chance of accidental discharge and reduce liability exposure. For industries where reliability and safety are non-negotiable, this technology offers a smarter path forward.

David N Lyman, a mechanical engineer with 40 years of industrial experience. Currently the president of RunDry Evaporators™.