The Growing Challenge

Any shop owner in the metal finishing business knows the headache of dealing with wastewater. Between chloride-heavy rinse water, spent plating baths, and various chemical solutions, you’re looking at serious disposal challenges. Most facilities I’ve visited are still stuck with the old hauling routine—and frankly, it’s becoming a bigger problem every year.

Any shop owner in the metal finishing business knows the headache of dealing with wastewater. Between chloride-heavy rinse water, spent plating baths, and various chemical solutions, you’re looking at serious disposal challenges. Most facilities I’ve visited are still stuck with the old hauling routine—and frankly, it’s becoming a bigger problem every year.

The costs keep climbing, you’ve got drums taking up half your floor space, and there’s always that nagging worry about what happens if something goes wrong during transport. I’ve seen too many shops get burned by disposal companies that cut corners or sudden price hikes that wreck your budget planning.

Why the Traditional Approach Falls Short

Let’s be honest about what hauling really costs you:

The obvious expense is the hauling fees themselves—we’re talking tens of thousands annually for most operations. But that’s just the beginning. You’re dedicating valuable floor space to storing drums of waste instead of productive equipment. Every time those drums move around your facility, you’re risking spills and the cleanup costs that come with them.

Then there’s the liability issue. Once that waste leaves your dock, you’re still on the hook if something goes sideways during transport or at the disposal site. I’ve heard horror stories about facilities getting hit with cleanup bills years after they thought a problem was someone else’s responsibility.

A Better Way Forward

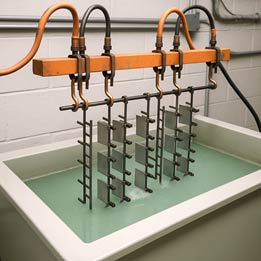

Smart shop owners are increasingly turning to evaporation systems, and the results speak for themselves. The basic concept is straightforward: remove the water, dramatically shrink the volume you need to dispose of. Most systems pull out around 90% of the water content, leaving you with a much more manageable concentrate.

What really matters is choosing equipment that can handle the aggressive chemistry typical in plating operations. You need chloride-resistant materials in all the wetted components—otherwise you’re just buying yourself expensive maintenance headaches down the road.

Taking It to the Next Level

Some facilities are going even further with advanced evaporation technology that removes virtually all the water. Instead of dealing with liquid concentrates, you’re left with just oils or dry solids to manage.

Some facilities are going even further with advanced evaporation technology that removes virtually all the water. Instead of dealing with liquid concentrates, you’re left with just oils or dry solids to manage.

RunDry Evaporators represent one approach to achieving complete water removal. The practical benefits are compelling: no more wastewater storage drums cluttering your facility, significantly reduced liability exposure, and much simpler compliance management.

The Bottom Line Makes Sense

When you run the numbers on volume reduction, the financial case becomes clear pretty quickly. You’re looking at immediate savings on hauling costs, plus you get your floor space back for revenue-generating activities. Most facilities find that the equipment pays for itself within a few years, then continues delivering savings for the entire system lifespan.

The predictability factor shouldn’t be underestimated either. Instead of dealing with fluctuating disposal costs and vendor scheduling issues, you gain much more control over your operating expenses.

Moving Forward

Every metal finishing operation faces unique wastewater challenges, but evaporation technology offers a proven path to better cost control and risk management. For shops ready to move beyond the limitations of traditional hauling, complete water removal systems represent a significant step toward more efficient and secure operations.

The question isn’t whether you can afford to upgrade your wastewater handling—it’s whether you can afford not to.